Mo-Sci has extensive experience in the manufacture of bioactive glasses. Bioactive glasses have the ability to bond to soft and/or hard tissue and are biodegradable in the body. The release of ions and the formation of hydroxyapatite, supports the regeneration of bone tissue and can accelerate the healing process. Our staff of glass engineers and technicians can research, develop and produce glass which is custom-made to fit your particular application.

Great care is taken in the manufacturing (batching, melting, grinding, forming, and packaging) of these specialized glasses to assure that they meet the high standards for medical products. These glasses are made from high-purity (analytical and reagent grade) chemicals, keeping unwanted trace impurities to a minimum. Precious metal or high-purity ceramic crucibles are used to melt glasses in dedicated furnaces and processed in an environmentally controlled space.

Learn more about calcium phosphate and other materials in our ebook, The Physician’s Guide to Synthetic Bone Grafting Biomaterials. Written by Mo-Sci CTO, Dr. Steve Jung.

Available Compositions

Target Compositions (wt%):

Custom compositions available upon request.

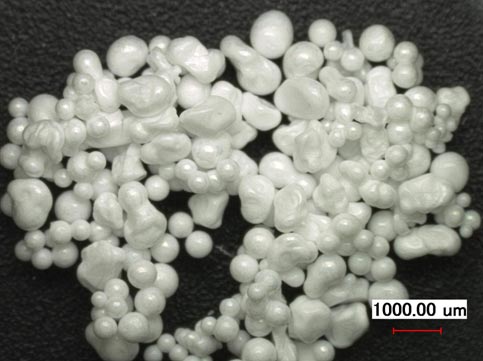

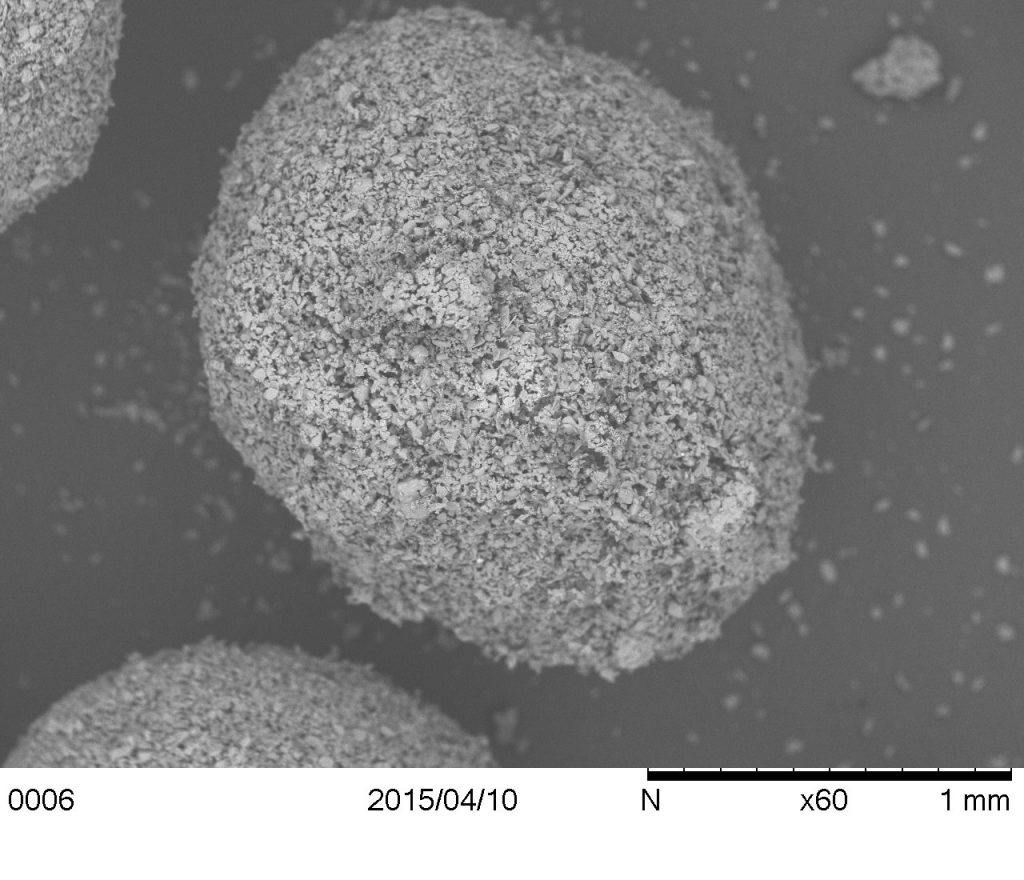

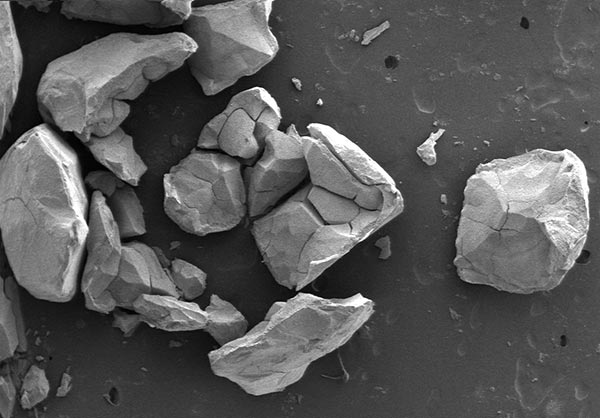

The bioactive glasses are available in sizes ranging from a few microns up to mm sized depending on the form of the glass. Mo-Sci offers bioactive glass microspheres, porous bioactive glass structures, and bioactive glass powders (frit).

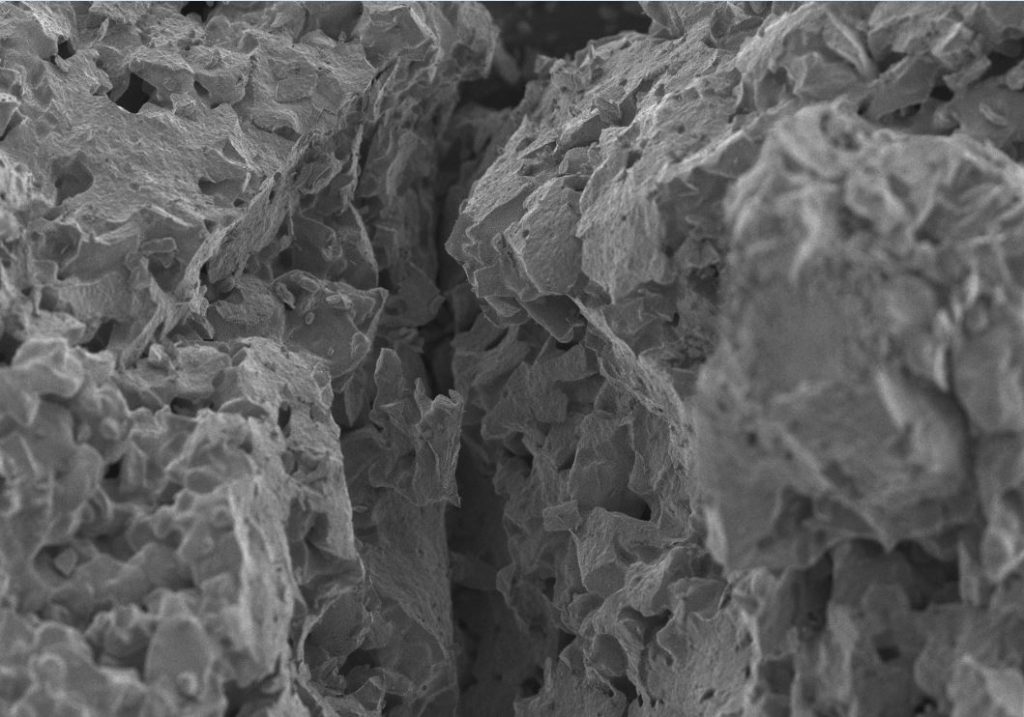

Porogran

Porogran is a patented form of bioactive glass material that has combined porosity with strength which allows for use as a granular material, or may be processed into putty or collagen strips without compromising the integrity of the scaffold. Porogran has an open porosity of ~45 to 50% for fluid and tissue infiltration, and an accelerated reaction rate compared to fully dense particles.

The Porogran scaffolds allow the device manufacturer to have large compressible materials in their device upon implantation, but react at rates similar to significantly smaller bioactive particles. this material can be manufactured in several popular bioactive glass compositions such as 45S5 and S53P4

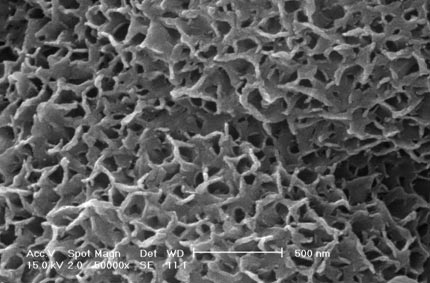

Hydroxyapatite

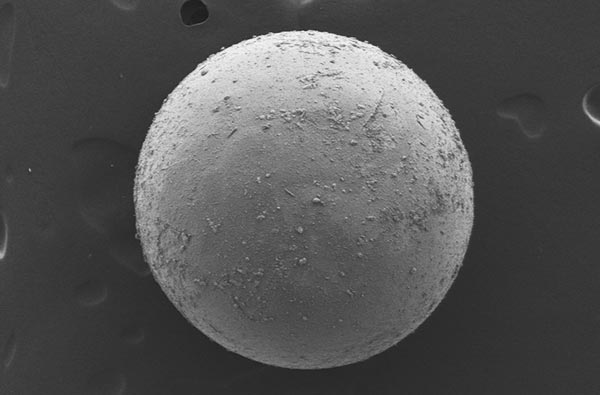

Hydroxyapatite (HA) media was developed as a high surface area material (> 120 m2/g) for possible applications ranging from water filtration for radioactive ions, ion chromatography, or biomaterials.

The biomedical field uses HA in bone grafts or other implants. HA is slow to react in-vivo, so the higher the surface area and the thinner the cross-section, the faster the HA will be remodeled by living bone. Hydroxyapatite Media offers a surface area up to 100X that of conventionally sintered HA materials.

Hydroxyapatite media is available in a range of sizes from 10 µm to > 1 mm and can be in the form of spheres, rounded particles, or irregularly shaped particles.